A customized mug makes the perfect gift for all sorts of people in your life, including your boss, a parent, a spouse, and hey, even yourself. If you’d like to get a mug printed with your own design, which type of paper would you use for this printing?

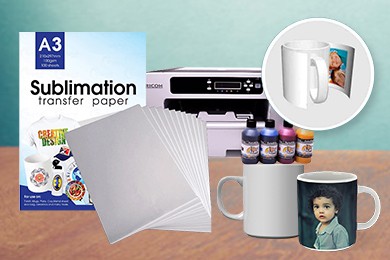

Mug printing requires a specialty paper known as sublimation paper. It has a coating that allows for ink absorption onto the material, such as your mug. It’s also important to use sublimation ink as well as polymer-coated mugs so the design transfers accurately.

In this article, we’ll tell you everything you need to know about sublimation paper for mug printing. That includes more on what this paper is, the other equipment needed, and how the printing process works. Keep reading!

What Is Sublimation Paper? Why Do You Need It for Mug Printing?

If you decide to print on a t-shirt or hoodie, you’d use a specialized printer to transfer the design directly onto the material, in this case, the shirt. However, trying to print onto a mug that same way would not work.

For one, what kind of printer can you fit a mug into? (They do exist, and we’ll talk more about equipment in the next section.) Also, would the design transfer right onto curved ceramic? This is also something we’ll get back to, but the answer, for now, is no.

When printing a design on a mug, you rely on a process called sublimation, which is when you dye a material, such as a mug, through pressure and heat. Sublimation printing isn’t limited to only mugs, as you can also print on items like mousepads and even hoodies using this method.

You can think of sublimation like stamping a design onto an item of your choosing. That “stamp,” so to speak, is known as sublimation paper. This isn’t your average loose-leaf paper or even printer paper.

Instead, sublimation paper has a coating on it that allows for optimal ink absorption. This paper is also adept at holding the ink in place so your design doesn’t print off-center.

Sublimation paper doesn’t do much on its own. It needs to be heated to activate, then it can transfer the design you selected onto your item, such as a mug.

We also want to take a moment to discern the differences between the sublimation paper and iron-on transfer paper. It’s true that iron-on transfer paper works in the same vein as sublimation paper since transfer paper also needs heat to activate. However, the iron-on design already has ink within it while the sublimation paper does not start with ink. Further, you cannot transfer a design on sublimation paper onto anything using an iron. It won’t work.

We recommend using iron-on transfer paper only for jobs where it’s required. This paper cannot be substituted for sublimation paper and vice-versa.

What Else Do You Need to Print onto a Mug?

Okay, so you’ve got your sublimation paper, but remember how we said it won’t be very useful on its own? If you want to do sublimation printing, you’re going to need more specialized equipment. Here’s what you should have before you begin.

Sublimation Ink

First, there’s sublimation ink. This ink is compatible with sublimation paper while other types of ink are not. As you recall, sublimation printing requires heat. With other types of ink besides sublimation ink, there’s the risk of the ink breaking down via hydrolysis. In other words, it will ruin your design.

Polymer-Coated Mugs

You also can’t buy any ol’ mug at a grocery store or department store and expect to use it for sublimation printing. You need one with a polymer coating, as the ink will create a bond with this coating. Here’s how to explain it scientifically: the ink starts as a solid. Then, when you add pressure and heat through sublimation, that solid ink becomes a gas. The gas covers the polymer, getting deep into its surface. Without this coating, the design won’t transfer.

Paper Cutter

Depending on the size of your polymer-coated mug, you may need a paper cutter to slice the sublimation paper to a certain size. For example, if you have a standard coffee mug, you might trim both the shape and the length of your paper to better fit the mug.

Any paper cutter you have lying around is sufficient for the job, as is a pair of scissors. Just cut carefully, starting with more than you need. You can always cut more off, but you can’t add back what you trimmed, not without risking the integrity of the design.

Heat Press

By far, one of the most important pieces of equipment for sublimation printing is the printer itself, or the heat press. These presses are available for both vertical and horizontal printing. If you had a taller design, like that for a coffee mug, then you’d rely on a vertical heat press. For all other mug shapes and sizes, a horizontal heat press would work.

How to Print on a Mug

Now that you’ve familiarized yourself with the equipment necessary for sublimation printing, you’re ready to print your very first mug using a heat press. Here are the steps to follow for success.

Step 1: Selecting Your Design

The first step is one the most fun parts of the process, as you get to choose the design you will print onto your mug.

You have nearly countless options here. If you drew up some cool artwork yourself, then you can print this onto the mug. You could also take a photo and transfer that, such as a prized family snapshot, a great vacation memory, or even a picture of your grandchildren or nieces and nephews.

If you’re more business-minded, then a company logo would look fantastic on a mug. You could sell these mugs or even give them to customers when you strike a deal.

Step 2: Choosing Your Mug

With your design picked, you now have to match it to a mug. If your design is taller than it is wider, then you need a mug with an equally long profile. For a wider design, smaller, squatter mugs are your best bet.

As you shop for your mug, you may want to print a picture of your design (on plain ol’ printer paper) and carry it with you. If you find a mug you like, hold the picture up to it. Is the design too big or small for the mug? Then keep looking.

A tall design on a wide mug will cut the top or bottom off, which will look unappealing. Printing a longer design on a smaller, wider mug will look squished and awkward, neither of which you want.

If you find your perfect mug, remember that it must have a polymer coating! Otherwise, you can’t print on it.

Step 3: Cutting Your Sublimation Paper

Next, you want to trim your sublimation paper to the size of your design. If you had previously printed your design on printer paper, then use this as a guide to cut your sublimation paper to the right size. Again, normal kitchen scissors are fine for this, as is a paper cutter.

Step 4: Picking Your Heat Press

Like you had to put some thought into which mug to use for your sublimation design, the same is true of the heat press. If your design is taller, then you want a vertical press, and, for shorter designs, a horizontal press.

Step 5: Printing the Mug

Now comes the most important part of the process, the actual printing. Double-check that you have the right heat press for your mug design. Place the sublimation paper into the press. It’s up to you how hard and how long you will push down on your heat-press. Doing so creates the heat and pressure you need, but pushing too hard on the press could skew the accuracy of the design transfer.

Your heat press should come with instructions, including usage directions that tell you how long it’s recommended you push on the press. Please follow these instructions for the best results.

With the press in action, it becomes a sort of like an inkjet printer, but of the sublimation kind. Spray nozzles release the ink, which passes through the sublimation paper. As the ink goes from liquid to gas form, it attaches to the polymer of your mug, printing the design.

If all goes well, then when you finish with your heat-press, your design should have transferred onto the mug flawlessly.

You can see a mug is printed using a heat press right here on YouTube:

Conclusion

Mug printing is a fun activity you can do at home with a heat press. You also need sublimation paper and sublimation ink, both of which react to heat and pressure to recreate your design on the mug. That said, your mug must have a polymer coating, as the ink will bond to the polymers. Without the coating, the printing won’t work. The next time you need a great gift for a special person in your life, a custom-printed mug will surely put a huge smile on their face. Best of luck with your printing!